LET'S TALK ABOUT CASING MODIFICATIONS

Modifications can be a headache — we’re here to help.

Clearance for the differential carrier, crown wheel and crown wheel bolts should be checked by progressively fitting each part to the right-side case. Its finished appearance should be similar to the left side case when complete.

If you’re using the transmission in its 4WD state, that is the extent of your case modifications — move on to fitting the Subarugears ring and pinion and differential set up.

clearance the case

Shortening the AWD case to a 2WD case for Beetles, Kombis, Vanagons

As we are only using the 2WD part of the transmission, the casing can be shortened to 565mm length (plus 80mm length of shifter support tube that is placed over the top of the torsion bar). This should be performed on the later style center differential housings from 1999 onwards ( 8 bolt or TY754/755/758).

Earlier style centre housings (4 bolt TY752) are difficult to shorten effectively. These are identified by their square panel on top of the centre differential case. Newer centre differential casings are interchangeable with older style casings.

Alternatively, you can purchase our Subanose — one piece cast nosecone compatible with all 5 speed Subaru transmissions. No need to use a grinder or TIG weld, simply transfer the parts from your donor center differential housing and bolt it all on. The shape has been optimised to give the shortest possible shifter support length and maximum clearances.

Mark the cut-out line

9cm (3 1/2 inches) from the end with the cast bosses for the mounts. Do not mark all the way around — leave the base of the shift rod support tube unmarked and uncut. Carefully mark above and below the shift rod support tube. The castings are thin there and are easy to cut through.

Be very careful — there is a bolt just to the right of this round plate (gearshift interlock) that holds a ball and spring in place. Do not grind off the bolt. Do not grind down the flat mounting surface for this bolt or the tension that the ball and spring places on the interlock will be incorrect.

Note there are three holes to fill:

- Large hole with Subaplug.

- Hole on inside of shifter support shaft, filled with TIG weld, threaded plug, Devcon or Silicon.

- Weird-shaped hole on right hand side, filled with TIG weld, Devcon or Silicon.

After some finish grinding and flap disc work plus holes filled with Subaplug, threaded plug, TIG weld.

Complete shortened Subaru transmission casing

The casing needs to be welded in three areas :

- On the shift rod support.

- On the outside of the threaded hole that holds the oil splash catcher on the inside.

- In the area where the steel welch plug from casting has been removed.

Shorten the casing

Case breather

The Subaru transmission has a small case breather built into the dipstick. Since the dipstick is no longer able to be used and the dipstick tube is sealed, a case breather should be built into the transmission in order to relieve pressure build up.

Subarugesars supplies a dipstick cover with each kit. This is a hi-temp silicon cover that ensures the oil flung up by the reversed ring gear does not get pumped out of the transmission. In order for the transmission to ‘breathe’ once the oil gets hot and expands/aerates, a breather hole in the casing is required.

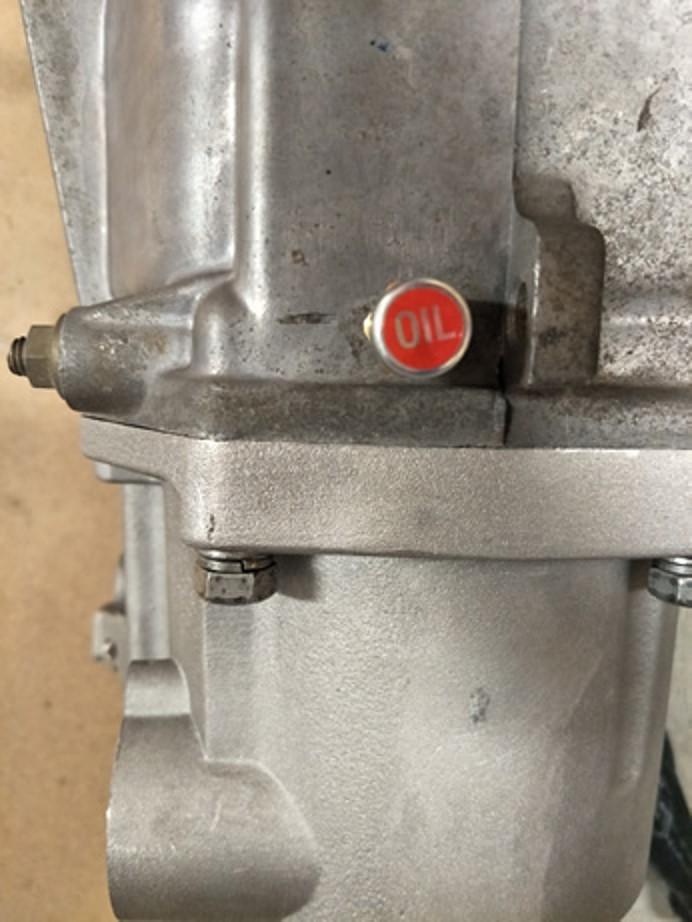

The ideal location for the case breather is in the rear of the transmission case, as far out of the way from flinging oil as possible. The suggested case breather consists of one hole just above where the nosecone joins the main case — on the starter motor side. This area is a hollow casting area protected by the horseshoe.